3D printing isn’t new, but it’s finally hitting the point it’s more mainstream than experimental. You take ingredients, a shape you want to recreate, compute thin cross-sectional slices, and use an additive printing process to deposit layers to create the object. This can range from food products to concrete, but most commonly uses plastics, resins, or foods at a consumer level.

Depending on the printer, the technique, and the materials, you can make many different things. I’ve personally printed kids toys, parts for things, home decorations, musical instruments, and more, and that’s barely even scratching the surface of what 3D printing can do. Let’s go over how 3D printing works, its uses in industry, the state of consumer technology, and how to get started.

3D printing has been “a few years off” for decades (since I started high school). The big issue was nothing ever hit the right quality to cost ratio to make it worth considering (for more than a passion project). It cost several thousand to get started, and the prints looked like dollar store items which sat out in a hot car in the sun. Things have changed in the past few years with even cheap out-of-the-box printers delivering a print capable of replacing purchases with minimal effort.

How 3D Printing Works

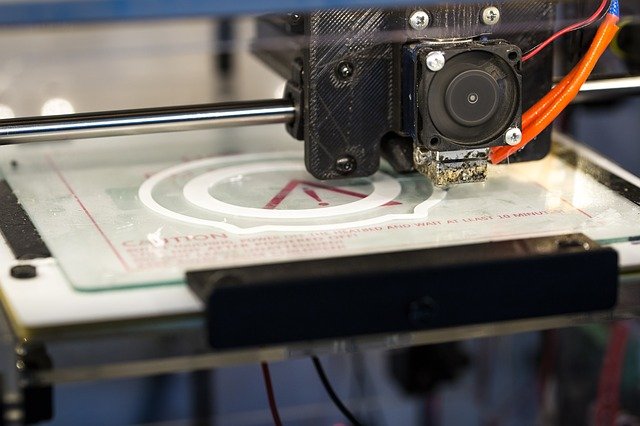

As mentioned before, 3D printing basically works out to taking raw materials, telling a system what you want to make, then using a process to actually make said item. Each object is run through software which takes something like an STL (stereolithography) file which is broken down into smaller cross-sections (in a process called slicing).

Most (consumer) software breaks this down into a format called G-code which basically is a language that tells a CNC system (its original purpose) or similar motor system how to move and what to do (e.g. cut or extrude heated plastic, or shine a UV light on resin).

Basically, you take a file of an object as you want it and calculate out how to make the 3D printer slice it into layers which are then printed one on top of the other to create the full object. This forms an additive process where layer upon layer is plastered on the layer below. For more complex structures, this may necessitate the use of supports. Structures which get a bit top heavy may require rafts below to build a supported base.

Materials can differ depending on the types of 3D printing. Some devices may use edible substances, others plastics, and others concrete and so on. There are a lot of types of 3D printers and each has a different purpose and a different function. Some build houses, others build toys. Others make art.

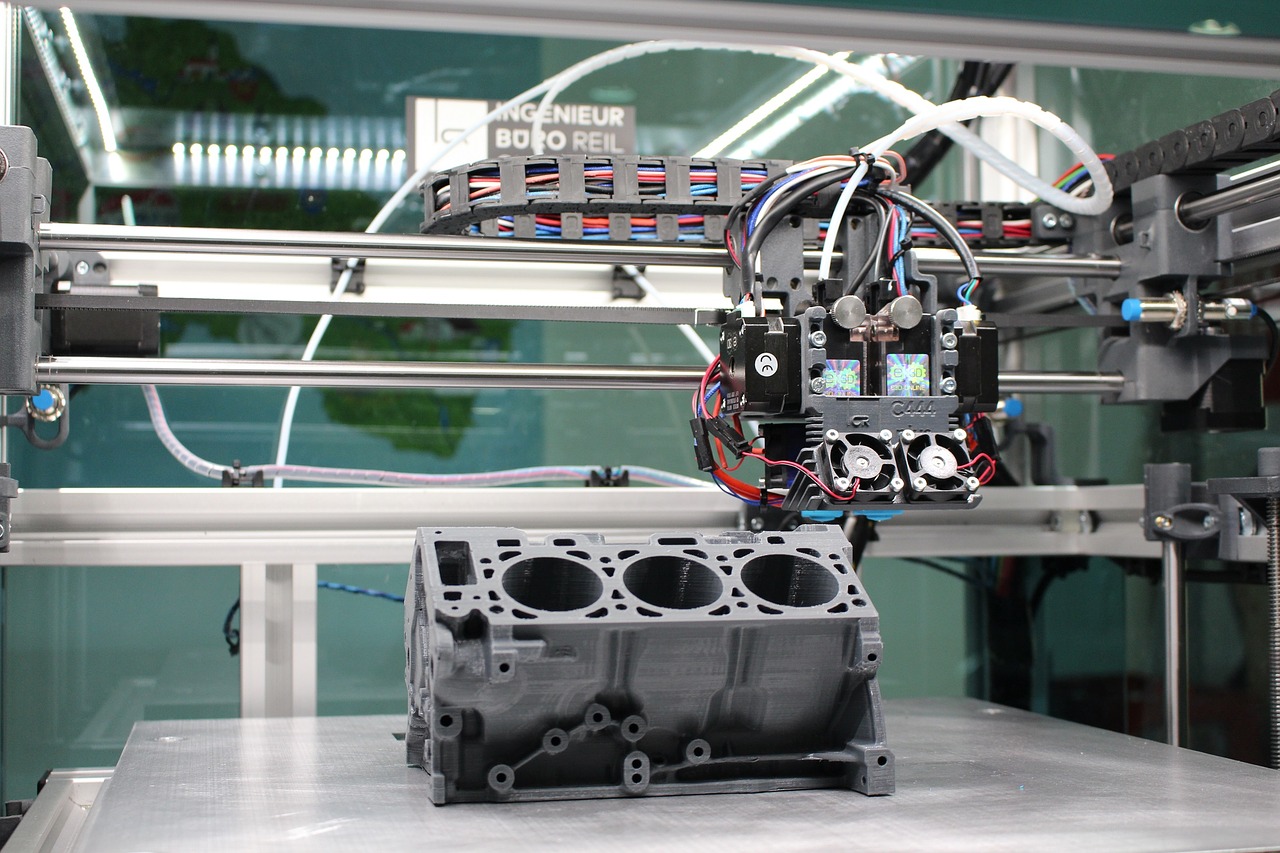

3D Printing in Industry

Additive printing has been a common concept for ages. Pizza, sandwiches, cakes, etc. are all built with layers which are added one on top of another. The assembly of a pizza involves dough, tomato sauce, cheese, and toppings (although the order may vary for some types of pizza). A startup from the UK experimented with a primitive form of 3D printing and automation for making a pizza on demand without a human involved for the actual creation.

There are many different offerings on the market for 3D food printers. 3D printing for foods has touched on meat alternatives and more. I expect we’ll see even more advanced 3D printing technology for cell cultures and similar with artificial, lab-grown meats.

Concrete and similar have seemed like good candidates for 3D printing, and some companies have taken to 3D printing buildings. More and more projects are popping up around the world to solve housing issues with automation.

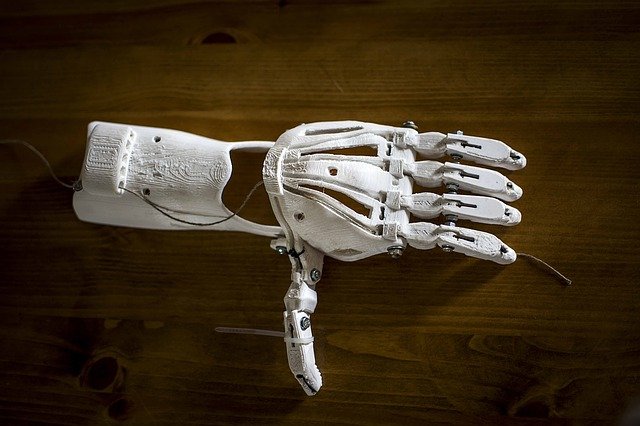

The medical industry has made use of 3D printing. Advancements have meant the theoretical creation of replacement organs without the same complications as transplants and more affordable comfort and functionality for prosthetics. There are bone printings and similar processes which have revolutionized the potential of the medical world.

Many other industries are using 3D printing. It makes for cheaper parts for specialty manufacture (especially with the right finishing process). Why purchase a 50 pack of custom bolts for a non-critical part when you only need one for a proof of concept? Prototyping and other industry applications have created a great use case for 3D printing and a way to accelerate development without raising costs.

Consumer Technology

Consumer 3D printing has been “right around the corner” since I was starting high school, but there wasn’t anything that made sense for any level of consumer. When I first started college, an “affordable” 3D printer came out to only cost $5,000 to build and could print things that looked like scuffed vinyl which sat out in a car in the sun, and that was after “finishing” it. You could get it for something like $3,000 if you built yourself and printed or created parts. I don’t know if those prices included markup or if it was just what we could get where we were.

I researched 3D printing a few years ago and just couldn’t justify it. The price wasn’t bad, but it was still a bit high. The biggest issue was with quality of print and longevity of the devices. They weren’t cheap like they are today, and they didn’t print as effectively as modern machines (let alone as fast). Parts were more expensive, special order, and not as good of quality either. Filaments weren’t available in most hobby stores or even online in a convenient form either.

The seed of potential was planted though, and I have been watching the technology ever since (and bought in last year when the cost to quality threshold reached my minimum). I have long since dreamed of the days I could just print an ocarina or a random part around the house. I wanted a physical outlet to make things which combined my love of technology and art. Those days are here, with some caveats.

I’m about to drop a lot of affiliate links, but most of them are just for examples of products. That said, I’m going to include what’s worked for me or what I’ve heard about.

3D Printer Types

We’re going to ignore a lot of the industrial offerings and just focus on what makes sense for a hobbyist or home user. 3D printers for home use (outside high-end culinary and similar) boil down to filament printers and resin printers. We’ll divide each type up and explain what it is and how it works. There are many other subtypes, but I’m only going to focus on what makes sense at a consumer level (Fused Deposition Modeling [FDM] and Stereolithography [SLA]).

Some of the other types are probably becoming commercially viable as I write this, but I don’t tend to be an early adopter either. This is what works as of 2021.

Filament Printers (FDM)

Filament printers extrude filament from a heated end. You get something which takes a line of filament, heats it, and prints it on a bed to build layers. Most move along an X, Y, and Z axis with most printers moving the bed for the (traditional) Z (Y for printers), then the X is controlled by a mounted extruder on a belt and the Y (Z for printers) is controlled by a rod system which moves it up or down. This is a standard Cartesian style printer, but there are other types too.

Delta 3D printers use 3 “arms” to move and deposit material. The system works off of angular deltas for each arm which move up and down to move the hot end. There are also CoreXY systems as well. These printers are really cool, but are harder for newer enthusiasts to use and have more caveats. Some trade accuracy for speed, others difficulty for efficiency.

I personally used the Creality Ender 3 V2 and heavily modified it. I love open source for several reasons: it means that you can theoretically maintain things you truly care about and have insight into the process. The Ender 3 is open source and the community has committed to modifying it to make it do more than it could before. Half of the fun of 3D printing is chasing the best print.

Creality Ender 3 V2 Upgrades: What to Look for with Other Printers

Modifying little things can make it feel like a new or better printer. You can add some new springs to the bed and it becomes much more predictable for leveling. The bed is where everything is built, the more predictable, the better the literal foundation for your prints.

You can add an auto-leveler and get to printing faster. I don’t need to run a leveling process and drag paper under the nozzle, I just hit a button. Time is money and this addition definitely outpaces any minimum wage job by leagues within the first few prints.

Higher quality tubing can make the printer function much more efficiently with less effort. Capricorn is the standard for quality with most enthusiasts. Other options exist, but as of writing, it’s the cheapest that gets you the best results for a part which will wear out over time.

Minor things like bed coatings can also make a world of difference on a print. You can either upgrade the bed or just put down some stuff to help. You can also do both for even better results. Bed coatings have always provided value for every kind of print I’ve done.

These printers offer a world of configuration that most consumer technologies don’t anymore. You could just set it up out-of-the-box, or you could factor in the cost to get a better print with less effort. Resin printers don’t have as many options, but there’s still a world of exploration in modifications.

Filament Types for FDM

The filament used also impacts the results. Most people use standard PLA (Polylactic Acid) filament to start out and for many projects. This filament is produced with renewable resources (usually corn) and is compostable (but with stringent conditions including temperature, O2 levels, etc.). Not exactly ideal, but better than most plastics on the market.

ABS (acrylonitrile butadiene styrene) filament works out as the better choice for parts and pieces which will see wear and tear. Most filament 3D printers can handle ABS, but it does take some planning. There’s an odor, as well as temperature requirements. It is also a bit more susceptible to contractions from temperature. To top it all off, it also takes a toll on most consumer grade printer hot ends.

PETG (polyethylene terephthalate glycol) filament can help make food-safe 3D prints. There are obviously some caveats. Even PLA can be food safe, but tends not to be in practice. PETG is a traditionally food-safe plastic from several definitions though (so long as you avoid getting materials with the wrong additives).

ASA (acrylate styrene acrylonitrile) filament is similar to ABS, but known for better UV resistance. It’s similar to ABS in that it off-gases (it releases toxic fumes and requires ventilation more often than not), but ASA is a bit more resilient than even ABS. That said, it makes some smooth prints with some great properties for real world usage over the others at the expense of cost, maintenance, and warping like ABS.

The Software

Most modern filament 3D printers use Cura or similar to convert STLs to G-Code. Resin printers use similar with software which does similar. You can get a cornucopia of STLs from Thingiverse, but there are many sources. Some are paid, some are not.

Most printers just require you to convert an STL to a GCODE file and toss it on a micro-SD card (or flash drive) for the printer. Speed of the card really doesn’t affect the print either. Most printers won’t take anything too big (128GB or bigger) either.

Make sure you get something where the software is known to be okay. This boils down to the difference between loving to print and hating the process. Based on what I’ve printed, I’ve found some techniques work better than others, but I’ve never had software issues aside from bad files, bad designs, or major mistakes (e.g. not checking exactly how much filament is left or something).

I don’t know what alternatives exist to Cura, but I’ve found it to be more than enough for my printer. I’m sure there are plenty of features I haven’t unlocked, but at the same time, I also haven’t been held back by anything. The software behind a printer makes the difference between fun and misery.

The Results

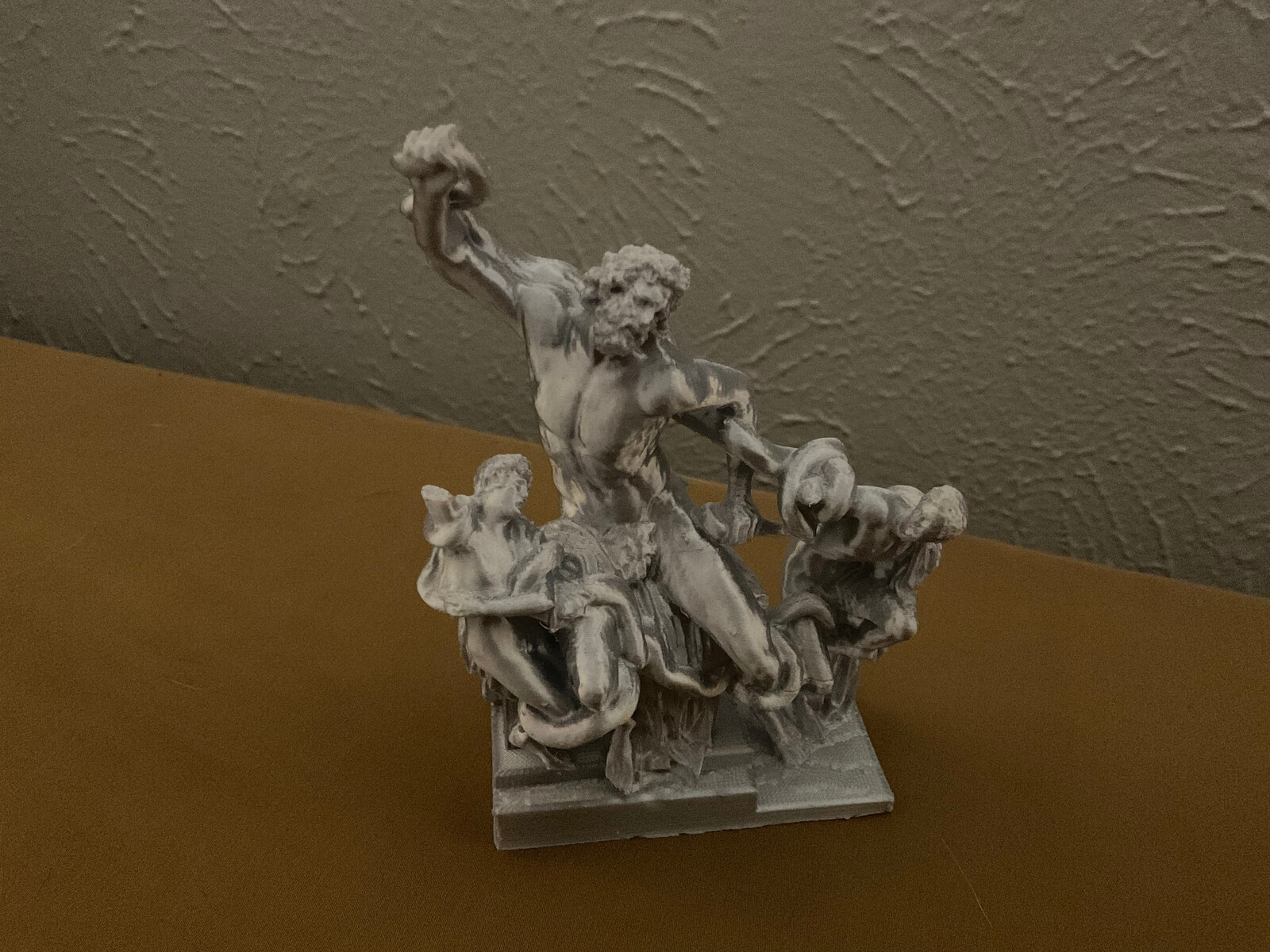

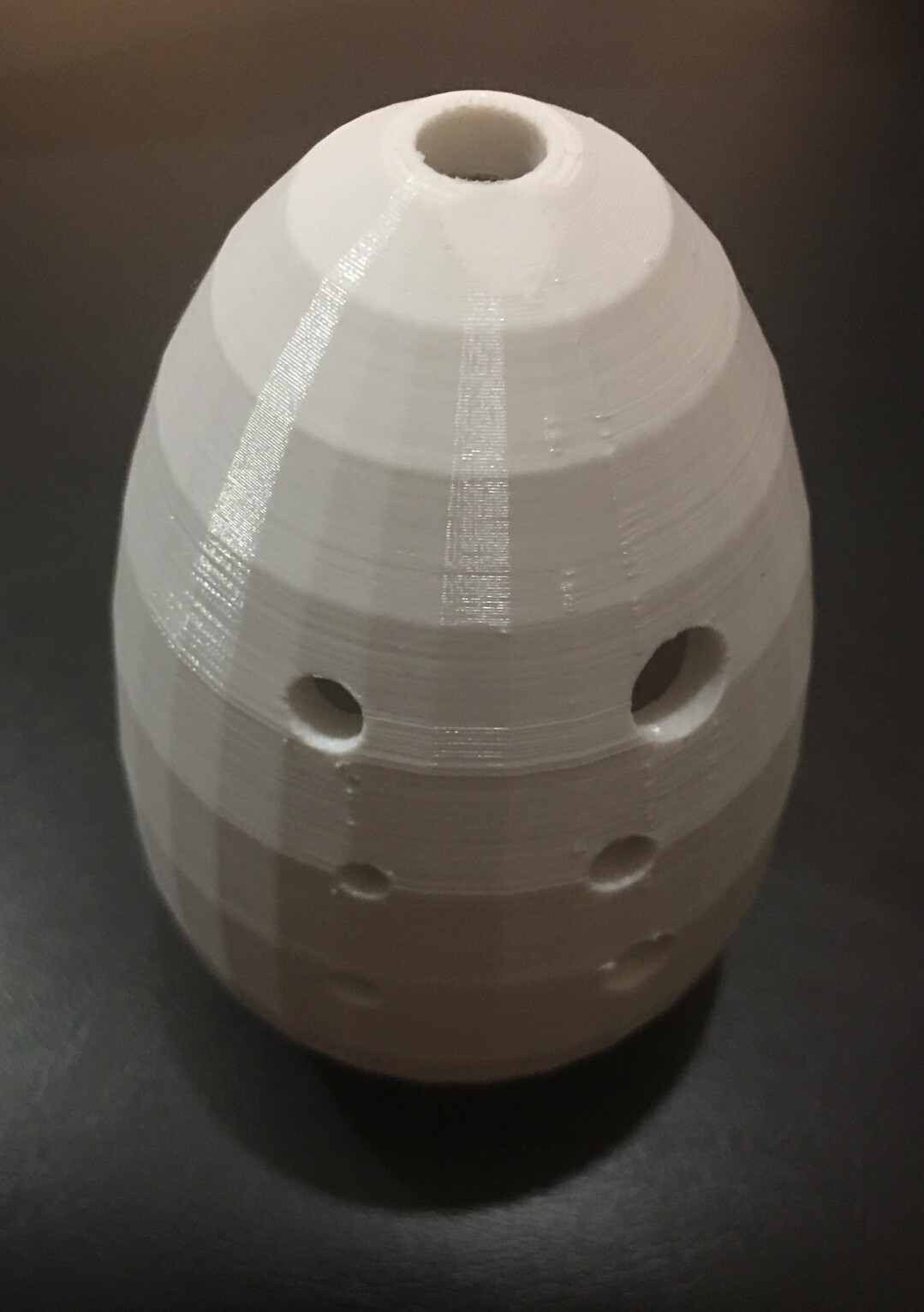

I’ve made musical instruments ranging from the Chinese Xun, to train whistles. There are projects ranging from religious imagery and classical art, to storage systems and functional parts. I mainly just print something and move on to the next project rather than perfecting things. I got into 3D printing to make things I need, not dawdle on perfection for individual items.

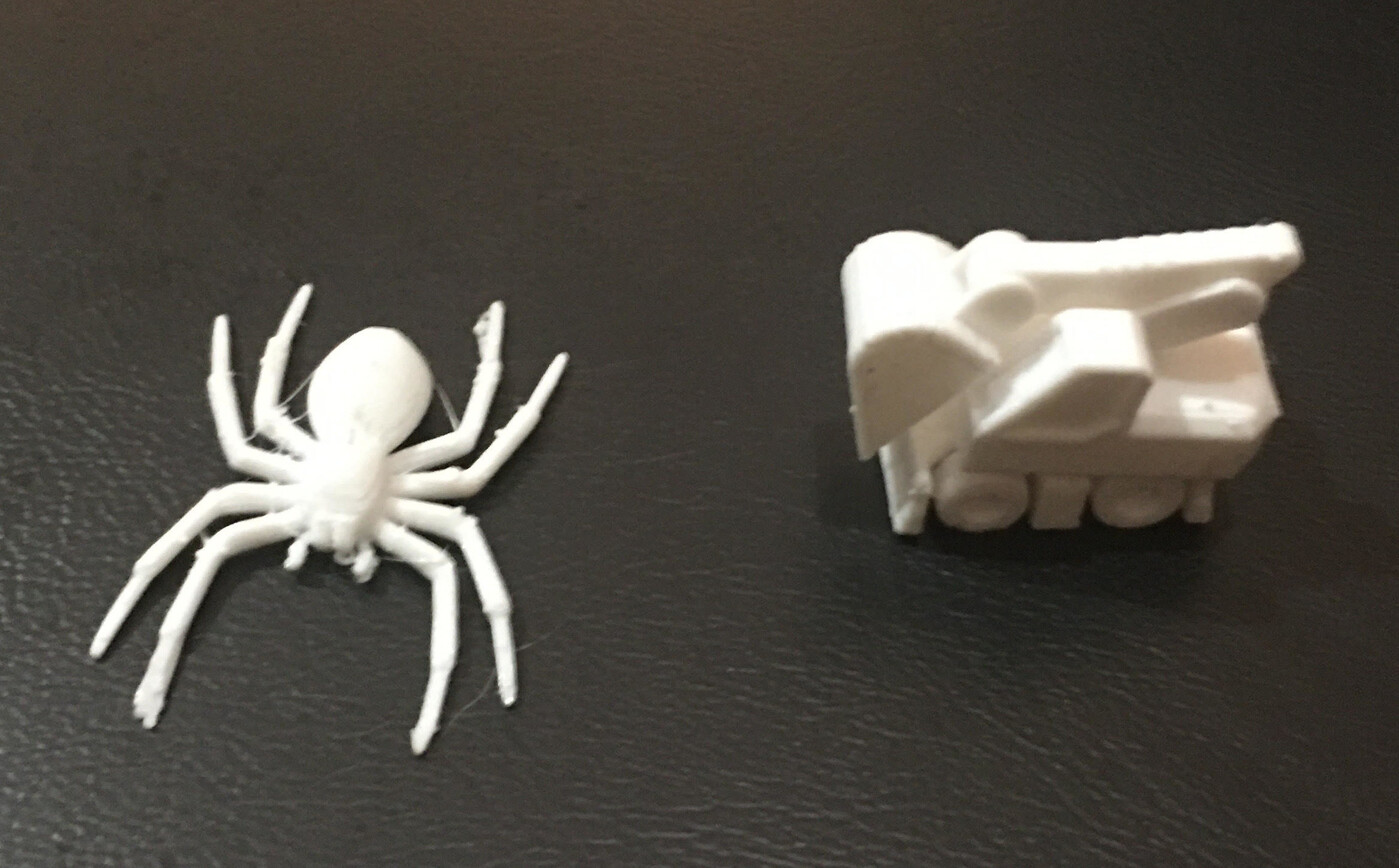

That said, I’ve also developed many props for my wife’s job in a daycare. There’s something about printing a small prop that eliminates the need to waste time or effort finding or developing something similar. Toy spiders are hard to get before Halloween, but it costs me pennies of filament to print something.

You can print toys or more if you find the right shapefiles too. 3D printing brought me a way to quickly satisfy phases for my child (and help her creativity as a toddler too). She absolutely loves the 3D printer and loves watching it print.

There are a bunch of aesthetic projects I’ve done for fun. We also have an easy way to print toys and pieces for games or similar. You can also print things for use in the kitchen, around the house, and in virtually every hobby. It’s possible to print tools and similar. It doesn’t need to last a lifetime, but it can get the job done.

More Results

My friend has a much better printer than I do. He was willing to share some images for many different projects he’s done. This is what you get when you really upgrade a 3D printer.

You can get more functional items like light switch covers. Incense burners and similar are all possibilities as well.

With a little effort on tuning and work with the printer, you can get even more. My friend has the same printer I do, but he’s modified it to where it isn’t even in the same class. It has the skeleton of the same printer, but it has been improved far past where my printer is. It was cheap for the level of improvement it yielded.

How to Shop for a Filament Printer

There’s no way I could fit a full guide to everything about buying a filament printer, but my first piece of advice would be to research well and ideally find someone who knows what they’re doing. There are many variables you’ll need to consider when purchasing a 3D printer. I personally like the Creality Ender 3 V2, but a lot of options have come on the market since I bought my printer.

How big are you planning to print? The print surface can impact what is possible and what is practical. Yeah, you can theoretically slice something in a bunch of pieces and acetone weld them together, but are you really going to do it? I know I just want to set it and forget it (except for complex projects).

Resin Printers (SLA)

Resin printers are a bit different than filament printers. They use UV-curing resin to create prints by curing the surface of a pool of resin as they move the print away. There are several primary types which use different methods to do the same thing when printing.

Basically, one type uses a vat with a tray which lowers while a UV laser shines across the surface to cure the resin as it sinks down forming layers. Another type uses a modified LCD to let UV light through in a pattern to cure resin as it is pulled out of a vat. Basically, you use UV to cure a layer as it is moved so that a shape forms. This method allows for extremely detailed prints with differing amounts of resin.

The biggest drawback to these systems is the cost of supplies to deal with resin, and the resin itself. Resin isn’t cheap, nor are the safety implements to work with it. The stuff will ruin furniture, clothes, and virtually anything unintended it gets on. You also need to deal with vapors and have the printer somewhere dark due to the fact sunlight contains UV which can ruin a print.

I really want one but it makes no sense for my living space. The idea is great, but there are a lot of caveats. This video explained it pretty well for buying one. I skipped out on a resin printer because I have a toddler and no space, but they’re definitely awesome if you can live with the limitations.

Making Things

There are a lot of websites which offer ways to make things. I prefer Thingiverse most because everything is free and most STLs I’ve downloaded have just worked. I’ve found everything from musical instruments to toys, from parts to functional tools. They have a little bit of everything, with most things tailored for a filament printer.

Cults is good too, but it has a mix of paid and free STLs. They have a lot of files really good for resin printers. There are also files for filament printing, but I noticed resin had a better representation when searching. That might be what I’m into, or just chance; I’m not entirely sure to be honest.

There’s also Prusa’s site. They have free files and a good selection of interesting projects. There are plenty of other sites with STL files, but these are some of the easiest to get started with. I’ve found countless things worth trying out on these sites. You can explore hobbies and interests without having to really commit.

Creation Automation

3D printing has ironically created a resurgence in 2D printing as well. The Cricut Maker and similar allow you to make custom printings for different types of items for customizations which used to be near impossible. You can print layered designs in materials ranging from paper to vinyl and beyond and adhere them to all sorts of surfaces (think T-shirts and cups among many others).

2D printing isn’t just inkjets, laser printers, and plotters; you have solutions like the Cricut or similar which print other materials. Brother has an offering, as do several other alternative brands. These devices allow you to shape materials in ways that were normally difficult and which required skilled effort to do right.

It’s nothing like 3D printing, but it allows a similar creative outlet. I have wanted a Cricut or similar for ages because of the potential. The other thing is 2D printing can lead to 3D items with the right creativity. Cutting vinyl a certain way can be sewn or otherwise mended together to create a 3D item.

Which came first is a bit immaterial, but the move to 3D printing has facilitated the moves in 2D printing which make it more advanced. Fine controlled motors and better processing made these devices more cost effective. Combined with demand for custom goods and individualized products and 2D printing and creation devices are a way to get creating unique items.

Getting Started with 3D Printing

3D printing provides an outlet for creativity that almost anyone can get involved with. Virtually anyone can learn the basics of 3D printing and learn how to get started making things. Most artistic or crafting endeavors take a lot more skill and effort to do something simple than printing. You can 3D print a simple nut, but what would you need to otherwise make one if the local store didn’t have one and you were in need? What about other things?

3D printing really gave me a way to try out new things without investing a ton. You could print some quick tools or items for certain hobbies without spending a fortune. I printed a Xun for less than a dollar that I still play. It let me scratch an itch without dropping real money.

What do you want to make and what kind of printer do you want? Resin printers are better for intricate parts or figurines like for Dungeons and Dragons or similar. Filament printers will excel at easy prototyping and functional items. Each also has a different amount of upkeep.

PLA can be used in a house easily, while resin may cast a toxic smell. Other plastics’ mileage may vary as well. You also have concerns of working with the end products. Resin printers require cleanup or surface preparation while filament printers just require you to finish some items.

What are you looking to make and why? I personally prefer my filament printer, but I can see why resin printers are popular. A resin printer wouldn’t work in my living space or with my needs, but it might for you.

3D printers allow you to create in ways you could only dream about before. What do you want to make?

Image by Christian Reil from Pixabay